- All our hydrogenation reactors are in accordance with ASME standards and relevant industry standards.

- Manufactured with strict production process and quantity control, the lifting weight of a single equipment can reach hundreds of tons.

- Self-tightening seal is adopted for the kettle body sealant.

- The safety interlock device ensures zero pressure operation to avoid injury.

- There are overpressure, over-temperature alarm device, in case of overpressure and over-temperature, PLC can reduce the pressure and cool down automatically.

- High utilization rate and sufficient reaction of hydrogen.

- Unique noise elimination device, low exhaust noise, in line with environmental requirements.

- The capacity of the catalyst in the reactor is maximized and the utilization rate of the catalyst is maximized.

- High overall equipment strength, the working efficiency is high, and the operation of each component is reasonable and efficient.

- Custom design and fabrication available

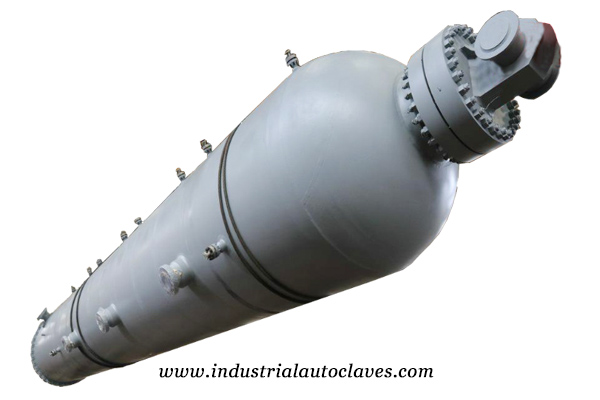

Hydrogenation Reactor

Description

Hydrogenation reactor is the kind of high-temperature and high-pressure container which is widely used for hydrogenation reaction, or in the occasion where liquid and gas need to be mixed adequately. It is the necessary equipment in the process of organic chemistry laboratory and petrochemical industry. Hydrogenation reactors are often used to convert residuum, a heavy part of the petroleum industry that is most difficult to use, into light oil to produce gasoline and diesel. Hydrogenation reactor also has a wide range of applications in chemical pharmacy. It can be used as the basic equipment for product development, organic chemical and pharmaceutical research, and can also be used for quantitative analysis of catalyst activity in industrial processes.

Commonly, hydrogenation reactors can be divided into two categories. The first one is a kind of liquid phase hydrogenation process used for high boiling point liquid or solid (solid needs to first dissolve in solvent or heat to melt) raw materials, such as grease hydrogenation, heavy oil hydrogenation cracking, etc. Liquid phase hydrogenation usually takes place under pressure. The process may be intermittent or continuous. Intermittent liquid phase hydrogenation usually adopts pressure kettle or bubbling reactor with stirring device. Continuous liquid phase hydrogenation can be carried out in trickle-flow bed reactor or tube reactor with gas, liquid and solid three phase continuous flow in the same direction. The second one is used for continuous gas phase hydrogenation process, such as benzene constant pressure gas phase hydrogenation to cyclohexane, carbon monoxide high-pressure gas phase hydrogenation to methanol, etc. The type of reactor can be row tube or tower type.

As the professional supercritical equipment designer and manufacturer, STRENGTH Equipment can design and manufacture the s hydrogenation reactor for your special requirements.

- Hydrogenation Reactor

- Hydrogenation Reactor Equipment

Hydrogenation Reactor Features

- All our hydrogenation reactors are in accordance with ASME standards and relevant industry standards.

- Manufactured with strict production process and quantity control, the lifting weight of a single equipment can reach hundreds of tons.

- Self-tightening seal is adopted for the kettle body sealant.

- The safety interlock device ensures zero pressure operation to avoid injury.

- There are overpressure, over-temperature alarm device, in case of overpressure and over-temperature, PLC can reduce the pressure and cool down automatically.

- High utilization rate and sufficient reaction of hydrogen.

- Unique noise elimination device, low exhaust noise, in line with environmental requirements.

- The capacity of the catalyst in the reactor is maximized and the utilization rate of the catalyst is maximized.

- High overall equipment strength, the working efficiency is high, and the operation of each component is reasonable and efficient.

- Custom design and fabrication available

Hydrogenation Reactor Applications

The hydrogenation reactor is the ideal equipment not only used for hydrocracking process, but also for hydrorefining process to remove impurities such as oxygen, sulfur and nitrogen in oil products, and to saturate all olefin and some aromatics to improve the quality of oil products in the petroleum refining industry. It can be used in coal chemical industry to produce liquid fuel by hydrogenation. In organic chemical industry, it is used to prepare a variety of organic products, such as carbon monoxide hydrogenation to methanol, benzene hydrogenation to cyclohexane, phenol hydrogenation to cyclohexanol, aldehyde hydrogenation to alcohol, naphthalene hydrogenation to tetrahydrothalene and decalene (as solvent), nitrobenzene hydrogenation to aniline, etc. In addition, the hydrogenation reactor is used in the refining process in the chemical industry to remove a small amount of harmful and difficult to separate impurities in organic materials or products. When propylene is refined, the impurities propylene and propylene are hydrogenated to form propylene. The hydrogenation reactor can put the use of carbon monoxide hydrogenation into methane reaction to remove a small amount of carbon monoxide in hydrogen.

About STRENGTH Equipments

Taian STRENGTH Equipments Co., Ltd is the professional pressure vessel designer, manufacturer and exporter dedicated in supplying finest quality industrial autoclave, supercritical equipment, hydrogenation reactor, storage tank and dish head products and solutions to worldwide customer over 20 years. We have over 80 talented research and development experts, 2 million square meters manufacturing factory and more than 50 sets large-scale manufacturing machines. Our annual industrial autoclave and storage tank output can reach over 300 sets, dished head output can reach over 3000 sets.

STRENGTH Equipments is not only manufacturing high quality industrial autoclaves, storage tanks and dished ends but also providing custom product design, fabrication and after-sale service. ODM, OEM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.