With the development of science and technology, supercritical carbon dioxide foaming molding technology has been widely used in various fields, and this process has gradually become a “dark horse” among technological forces and is constantly being pushed to the market.

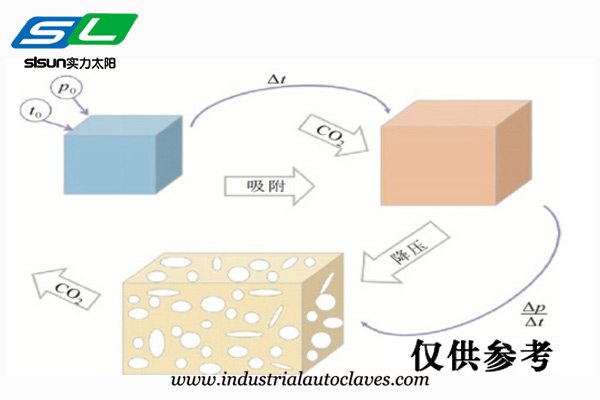

The principle of supercritical carbon dioxide foaming, the foaming process can be roughly divided into 4 stages:

(1) Make the supercritical fluid enter the polymer matrix to reach a saturated state to form a polymer/gas homogeneous system;

(2) A sudden rise in temperature or a sudden drop in pressure causes the gas in the homogeneous system to reach a supersaturated state, that is a thermodynamically unstable state, thereby causing bubble nucleation;

(3) The gas quickly diffuses into the bubble nucleus. And the bubble cells grow gradually;

(4) Rapid cooling to complete the shaping of the cell structure.

Supercritical carbon dioxide foaming is actually supercritical fluid microcellular foaming. The temperature and pressure are above the critical point, also known as supercritical fluid (Supercritical Fluid, referred to as SCF). Furthermore, the properties of supercritical foaming fluid are unique. And properties such as density, diffusion coefficient, and solvation ability are very sensitive to changes in temperature and pressure. Its viscosity and diffusion coefficient are closer to gas, while its density and solvation ability are closer to liquid.

The basic principle of microcellular foaming of supercritical fluid is to use the dependence of the solubility of gas in polymer on pressure and temperature. As a result, the polymer mixed system after supersaturated supercritical fluid enters a thermodynamically unstable state during the cooling process. So that the gas nuclei are formed. And then the microporous structure is obtained. Supercritical carbon dioxide foaming technology is a relatively effective method for preparing microporous polymer materials that has been developed rapidly in the past 20 years. The microporous structure here is similar to the popcorn structure. In recent years, it has been widely used in various fields.

Supercritical foaming materials are widely used in shoe materials, vehicles, sports equipment, ships, aerospace, furniture, etc. , decorations, toys, protective equipment and packaging industries.

It is believed that supercritical carbon dioxide foaming will be applied to more fields in the future!

About STRENGTH Equipments

Taian STRENGTH Equipments Co., Ltd is the professional pressure vessel designer, manufacturer and exporter dedicated in supplying finest quality industrial autoclave, storage tank and dish head products and solutions to worldwide customer over 20 years. We have over 80 talented research and development experts, 2 million square meters manufacturing factory and more than 50 sets large-scale manufacturing machines. Our annual industrial autoclave and storage tank output can reach over 300 sets, dished head output can reach over 3000 sets.

STRENGTH Equipments is not only manufacturing high quality industrial autoclaves, storage tanks and dished ends but also providing custom product design, fabrication and after-sale service. ODM, OEM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.