Automatic autoclave ( also called composite autoclave) is used for metal/non-metal adhesive components and resin based high strength glass fiber, carbon fiber, boron fiber, arylon fiber and other composite materials, such as aircraft doors, fairing, airborne radome, bracket, wing, tail, etc. The automatic autoclave is a set of system equipment, it can realize the sequential and real-time control of process parameters such as temperature, pressure, vacuum, cooling and circulation.

Main Subsystems of Automatic Autoclave

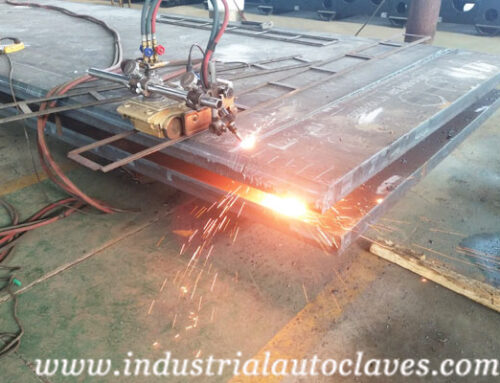

- Tank Body: High pressure and high temperature, with tank body, tank door mechanism, high temperature motor, wind tunnel plate thermal insulation layer, etc.

- Safety Interlock Device: High – voltage automatic interlock, manual interlock, high – voltage alarm device.

- Quick Opening Device: Manual and electric dual-purpose quick opening design, it can normally open and close the tank door in case of power failure.

- Tank Door Sealing Device: Tank door using silicone inflatable sealing, high pressure 400℃, no wear.

- Pressure System: Pressure transmission and control system, with compressor, gas storage tank, pressure control valve, pipeline, pressure transmitter and pressure gauge.

- Heating System: In the automatic autoclave forming process, the far infrared quartz electric heat pipe as the heating source, the fluid medium (generally air under low temperature condition, inert gas under high temperature condition) as the heat transfer carrier, and the fan as the forced gas circulation power to complete the process of the circular heating of the molding tool. In the cooling stage, the cooling process of the tooling is realized by circulating water to remove heat.

- Temperature Circulating System: With circulating fan, air guide plate and guide cover to accelerate heat conduction and circulation, forming uniform temperature field.

- Vacuum System: It consists of vacuum pump, pipeline, vacuum meter and vacuum valve, providing vacuum conditions for encapsulated composite prefabricated parts.

- Automatic Control System of Automatic Autoclave: It adopt Siemens PLC control system, to realize the pressure, temperature, cooling and other process parameters of the full precision control and real-time recording.

About STRENGTH Equipments

Taian STRENGTH Equipments Co., Ltd is the professional pressure vessel designer, manufacturer and exporter dedicated in supplying finest quality industrial autoclave, storage tank and dish head products and solutions to worldwide customer over 20 years. We have over 80 talented research and development experts, 2 million square meters manufacturing factory and more than 50 sets large-scale manufacturing machines. Our annual industrial autoclave and storage tank output can reach over 300 sets, dished head output can reach over 3000 sets.

STRENGTH Equipments is not only manufacturing high quality industrial autoclaves, storage tanks and dished ends but also providing custom product design, fabrication and after-sale service. ODM, OEM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.