Clad dished head is one kind of dish head, as a part of pressure vessel, connected with shell using welding type. For example, there are spherical shape, oval shape, torispherical shape, spherical crown shape, cone shape and flat shape, etc. According to the different clad dished head geometry . In welding, clad dished head is divided into butt welding head and socket welding head. And the head mainly used for different kinds of pressure vessel. Such as storage tank,heat exchanger, tower, reactor vessel and separate equipment, etc. The main material of clad dished head have carbon steel(SA516Gr70, A3, 20#, Q235, Q345B, 16Mn and so on), stainless steel(304, 321, 304L, 316, 316L and so on). And alloy steel (15Mo3 15CrMoV 35CrMoV 45CrMo ), Aluminum, titanium, copper, nickel and nickel alloy etc.

Firstly ,the end is consists of base material and clad material. Then the clad material as a usual is stainless steel. The base material as a usual is carbon steel. The reason to choose the carbon steel is that mainly consider its high strength. For stainless steel ,there is nothing to say more. Mainly considering its anti corrosion. Now the head is mainly used for the high pressure vessel industry. Its working medium needs anti corrosion. At now stage ,there are mainly explosive, rolling, diffusion welding, overlay, insert metal ingot method to production clad plate. This explosive method is the mainly used among these.

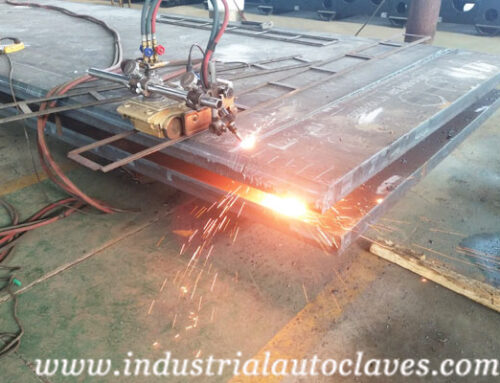

Process of clad dished head hot pressed forming mainly have the following:

- Making the workpiece into the furnace heat after heating to 380℃ in the furnace body. The heating temperature between 940℃and 950℃. During the heating process,controls to reach the heating temperature within 15 minutes. By adjusting the amount of fuel injection and then kept the temperature 5 min.

- Preheat the cavity to 500-550℃.

- Place the heated workpiece in the cavity for pressing, and the pressing time is 2-3min.

- Wind cooling theclad dished head to below 500℃ after pressed forming within 3min.

In a word, it should strictly control the heating process parameter. And holding time after workpiece preheat into furnace heating. So this can avoid effectively avoiding slow cooling to produce carbides. And can work a long life due to the short time pressed. It should cool the clad dished head below 500℃ by using wind cool within 3 min after forming.

As a usual , hot pressed is mainly used for a higher thickness clad dished head. It should choose a suitable manufacturing way depending on its thickness.

About STRENGTH Equipments

Taian STRENGTH Equipments Co., Ltd is the professional pressure vessel designer, manufacturer and exporter dedicated in supplying finest quality industrial autoclave, storage tank and dish head products and solutions to worldwide customer over 20 years. We have over 80 talented research and development experts, 2 million square meters manufacturing factory and more than 50 sets large-scale manufacturing machines. Our annual industrial autoclave and storage tank output can reach over 300 sets, dished head output can reach over 3000 sets.

STRENGTH Equipments is not only manufacturing high quality industrial autoclaves, storage tanks and dished ends but also providing custom product design, fabrication and after-sale service. ODM, OEM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.